High Performance Fibers

IZANAS®

IZANAS® is used in various fields because of its excellent properties.

IZANAS® is yarn made from ultra-high molecular weight polyethylene. It has the highest level of strength and modulus as an organic fiber (it is about 8 times stronger than piano wire with same weight). IZANAS® rope only with 10mm in diameter can support up to 20 tons (theoretical value).

Features

- Tensile strength and modulus

- IZANAS® has the highest level of strength and elastic modulus as an organic fiber material.

- Lightweight

- IZANAS® is a lightweight material with a specific gravity of 1 or less and floats on water.

- Weather and chemical resistance

- IZANAS® has excellent chemical stability and is highly resistant to light, water, organic solvents, acids and alkalis.

Applications

Taking advantage of the features of high strength, light weight, low elongation, abrasion resistance, and weather resistance, it is used in various fields.

Rope

Fishing Line

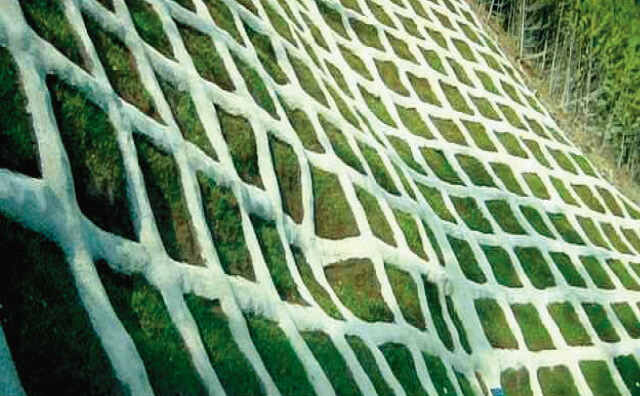

Net

Safety Gloves

Backpack

Reinforcement for Cement

Inquiries about this product

If you have any questions or concerns about our products, please contact us here.

Inquiries by email

Contact