Engineering Plastics

VYLOPET™

Polyester resin with excellent heat resistance and dimensional stability

VYLOPET™ is a thermoplastic polyester that showcases TOYOBO MC's advanced polymerization and compounding tecnologies.

VYLOPET™ is used in a wide range of applications, especially automotive, home appliance, and mechanical component applications.

Features

- Low water absorption

- Mechanical properties are not compromised by water absorption

- Dimensional stability

- Minimal dimentional changes with ambient temperature

- Heat resistance

- Can be used in high heat applications

- Good appearance

- Easy to achieve an excellent surface appearance

- High flow

- High flow properties enable thin-wall molding

- Electrical properties

- VYLOPET™ excellent electrical properties

Applications

Applications: Headlamp Bezels

Advantages: Low warpage, Heat resistance, High flow, Low outgassing

Applications: Electric Rice Cooker Parts

Advantages: Heat resistance, Flame retardance

Applications: Automotive Air Vent Fins

Advantages: High rigidity, Excellent surface appearance

Applications: Accelerator Pedal

Advantages: High rigidity, Two-shot molding compatibility

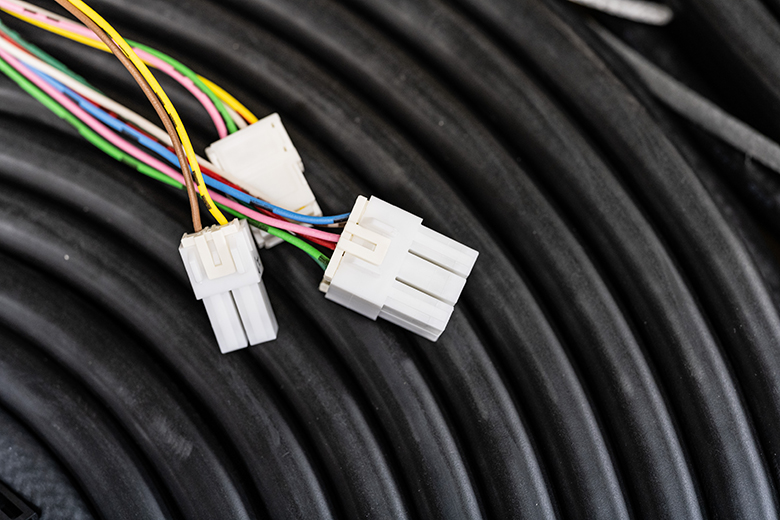

Applications: Connector

Advantages: Dimensional stability, Insulation

Applications: Breaker

Advantages: High rididity, Flame retardant

Inquiries about this product

If you have any questions or concerns about our products, please contact us here.

Inquiries by phone

Osaka head office

+81 6-6348-3771

Inquiries by email

ContactEngineering plastic lineup

Thermoplastic polyester elastomersPELPRENE™

Thermoplastic polyester elastomersPELPRENE™ Thermoplastic Vulcanizate ElastomerSarlink®

Thermoplastic Vulcanizate ElastomerSarlink® Higt-Performance Polyamide ResinGLAMIDE™

Higt-Performance Polyamide ResinGLAMIDE™ Biomass high melting-point polyamide resinVYLOAMIDE™

Biomass high melting-point polyamide resinVYLOAMIDE™ Thermoplastic polyester resinVYLOPET™

Thermoplastic polyester resinVYLOPET™ High Performance stampable sheetQuickForm™

High Performance stampable sheetQuickForm™ Elastic MonofilamentDIAFLORA™

Elastic MonofilamentDIAFLORA™ CAE SystemsCAE Systems

CAE SystemsCAE Systems