Products

Connecting the World

with Our Materials

State-of-the-art high-performance materials andenvironmental materials

Our materials are used in various products and solutions around the world.

Our strengths are leading to innovation for tomorrow, such as next-generation products aiming for a sustainable world and eco-friendly products.

Engineering Plastics

It is a plastic with excellent properties in terms of heat resistance.

It is used in automobile parts, electric/electronic parts, mechanical parts, etc.

Thermoplastic polyester elastomersPELPRENE™

Thermoplastic polyester elastomersPELPRENE™ Thermoplastic Vulcanizate ElastomerSarlink®

Thermoplastic Vulcanizate ElastomerSarlink® Higt-Performance Polyamide ResinGLAMIDE™

Higt-Performance Polyamide ResinGLAMIDE™ Biomass high melting-point polyamide resinVYLOAMIDE™

Biomass high melting-point polyamide resinVYLOAMIDE™ Thermoplastic polyester resinVYLOPET™

Thermoplastic polyester resinVYLOPET™ High Performance stampable sheetQuickForm™

High Performance stampable sheetQuickForm™ Elastic MonofilamentDIAFLORA™

Elastic MonofilamentDIAFLORA™ CAE SystemsCAE Systems

CAE SystemsCAE Systems

VYLON® HARDLEN®

We have an extensive product lineup, including high-molecular-weight saturated polyester resins

with excellent adhesion and durability, and adhesion promoters for polyolefins.

VYLON®Solvent soluble type VYLON®

VYLON®Solvent soluble type VYLON® VYLON®Solvent soluble type VYLON®

VYLON®Solvent soluble type VYLON® VYLON®Water-based co-polyester VYLONAL®

VYLON®Water-based co-polyester VYLONAL® Polyester modifierVYLON® RF series

Polyester modifierVYLON® RF series polyester urethane resinVYLON®UR

polyester urethane resinVYLON®UR polyamide imide resinVYLOMAX®

polyamide imide resinVYLOMAX® Resin for low pressure molding(solvent insoluble type)VYLOSHOT®

Resin for low pressure molding(solvent insoluble type)VYLOSHOT® conductive paste

conductive paste Tackifier for polyolefinHARDLEN®

Tackifier for polyolefinHARDLEN® Hot melt adhesive for polyolefinHARDLEN®

Hot melt adhesive for polyolefinHARDLEN®

Photo-Functional Materials

Printight®, a photosensitive resin letterpress printing material that can be developed with water.

We are developing original products such as the world's first full-scale photosensitive flexo plate "Cosmolight®".

Water-washable letterpress plate Printight®

Water-washable letterpress plate Printight® Water-washable letterpress plate Printight® CTP Plate

Water-washable letterpress plate Printight® CTP Plate Water-washable letterpress plate Printight® Pad plate

Water-washable letterpress plate Printight® Pad plate Printight® Sign plate

Printight® Sign plate Water-washable flexo plate Cosmolight®

Water-washable flexo plate Cosmolight® Water-washable flexo plate Cosmolight® CTP plate

Water-washable flexo plate Cosmolight® CTP plate Photopolymer film for screen printing Cosmomask®

Photopolymer film for screen printing Cosmomask®

Fine Chemicals

We are developing a wide variety of thio compounds, azide compounds, tetrazoles, carbodiimides, etc. by making use of the fundamental technologies we have cultivated over many years.

Environmental Solutions System

We have developed a device that concentrates VOCs into a gas with a small air volume and high concentration, and a VOC recovery device that uses activated carbon fiber.

Concentrators have been introduced in the fields of liquid crystals, semiconductors, paints and printing, and recovery devices in fields such as film production, converters and chemistry.

Brine Concentration systemHOLLOSEP MINI®

Brine Concentration systemHOLLOSEP MINI® VOC Concentration Apparatus HONEYROTOR®

VOC Concentration Apparatus HONEYROTOR® VOC recovery apparatus (nitrogen desorption type) K-FILTER®

VOC recovery apparatus (nitrogen desorption type) K-FILTER® VOC water treatment apparatus K-FILTER®

VOC water treatment apparatus K-FILTER® VOC recovery apparatus K-FILTER®

VOC recovery apparatus K-FILTER® VOC deodorizer (KR), concentrator (KU)K-MATROLL®

VOC deodorizer (KR), concentrator (KU)K-MATROLL® Catalytic oxidation apparatus, direct combustion apparatus, regenerative combustion apparatus Combustion apparatus

Catalytic oxidation apparatus, direct combustion apparatus, regenerative combustion apparatus Combustion apparatus

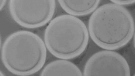

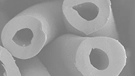

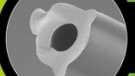

Water Treatment Membrane

We offer a variety of separation membranes, including hollow-fiber RO membranes that convert seawater into freshwater, low-pressure spiral-wound RO membranes, BC membranes capable of further concentrating seawater and industrial wastewater, FO membranes that enable membrane separation at lower operating pressures than RO, and MF membranes that can be used for MBR.

High Performance Fibers

We have developed three different types of super fiber products, namely Izanas®, Tsunooga®, and Zylon®, which are used in a variety of fields that support our lives.

BREATHAIR®

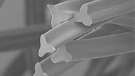

A structure in which polyetherester elastomer fibers with rubber elasticity are connected in a three-dimensional direction while drawing many loops.

It is widely recognized as a cushioning material that can replace urethane foam, such as for bedding and Shinkansen seats.

Polyester staple fiber

We handle high-performance staple fiber products, including composite fibers "Toyobo Ester®" (there is also a single polyester component) that uses polyester for the core and polyethylene for the sheath.

Toyobo Ester is used as a raw material for nonwoven fabrics for hygiene products such as diapers and sanitary napkins.

Life Material

We handle high-performance textile products used as filter cloth materials for high-temperature bag filters.

A unique product lineup with excellent heat resistance, chemical resistance, and dust collection performance.

SPUNBOND

High-performance spunbond nonwoven fabrics are popular not only for automobile interiors and industrial materials, but also as anti-grass sheets and civil engineering and agricultural materials that protect crops.

AC Material

In addition to the dust removal filter that collects dust by electrostatic force, the deodorizing filter using activated carbon,

Filters with both dust removal and deodorizing functions are available.